Description

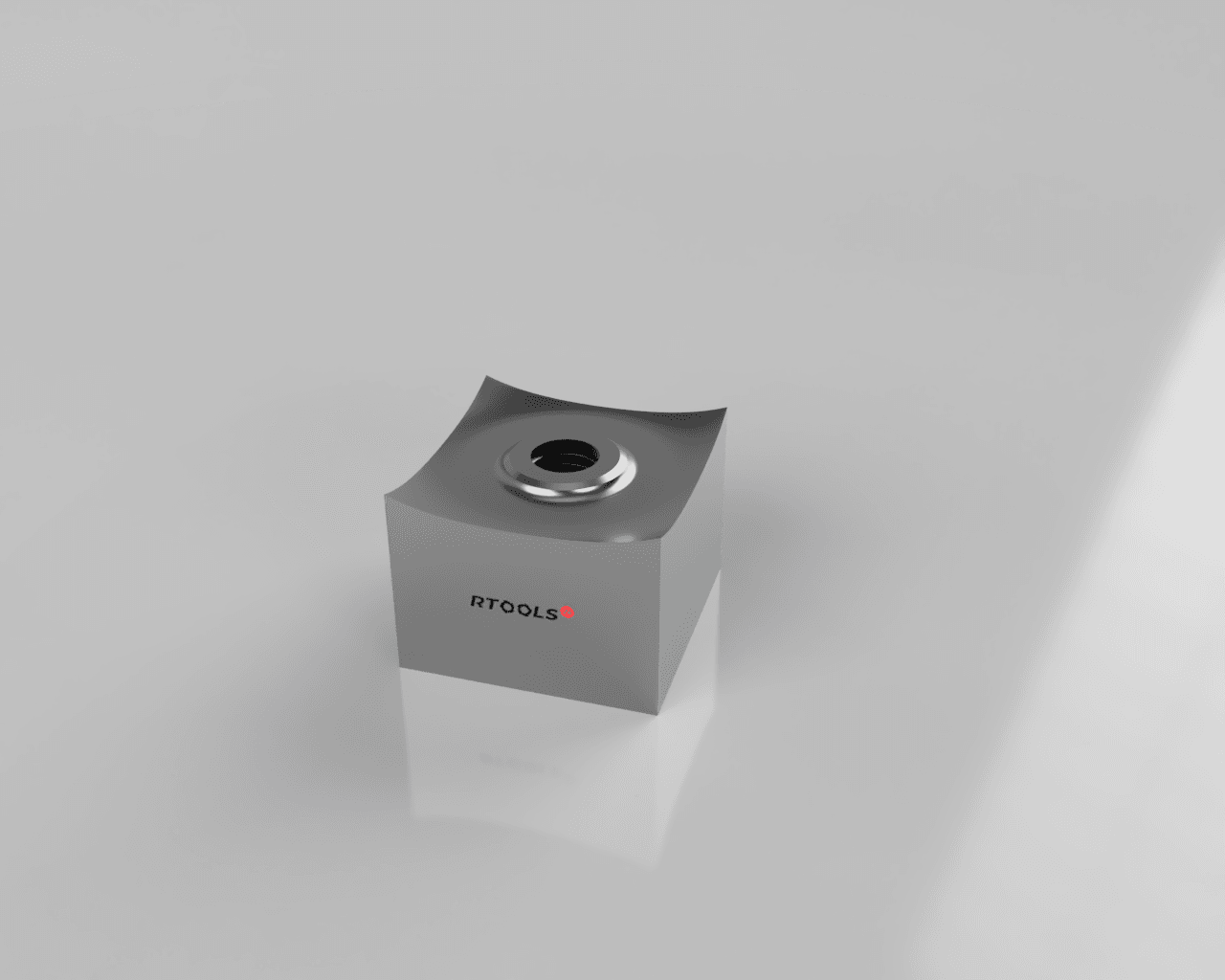

Concave cutter– 40x40x30–M12 (R26)-ECO

CUTTING PERFORMANCE AND DURABILITY:

Thanks to the use of appropriate steel grades and different shapes, the spare part offered by us corresponds to the quality of parts produced by the manufacturer for the first assembly.

This cutter is made of tool steel and corresponds to the quality of the original blade assembled by the Manufacturer.

The hardness achieved in the process is external case-hardened, which allows the blade to wear evenly. The hardness of the material is only on the external surface, what gives the higher resistance to brake in the core which have higher resistance to impact.

Shredding with the use of this blade is efficient, the knives do not wear with the same dullness as the original cutters mounted in the shredder.

In order to avoid breakage and damage to the shredder, welding and surfacing of the blades is prohibited, as this can cause breakage as a result of damage, the chipper.

GENERAL CHARACTERISTICS:

Shredder cutters are manufactured in Poland from certified tool steel.

They are subjected to quenching at certified heat treatment facilities in Poland.

APPLICATION/ MATERIALS:

Substitute fuels; Domestic waste; Bulky waste; Foils; Plastic; Files & data carriers; Paper

Made in Poland = Top Quality

Note:

Knives | knife | concave blade and cutting crowns | concave shredder | crown cutter

Our products are not made by the machine manufacturer, but thanks to our knowledge perfected in this field over the years, they are a very good quality equivalent ensuring quality not worse than parts for the first assembly.

In many cases, the modified heat treatment process and proprietary mechanical treatment solutions translate into better durability of RTOOLS knives.