Description

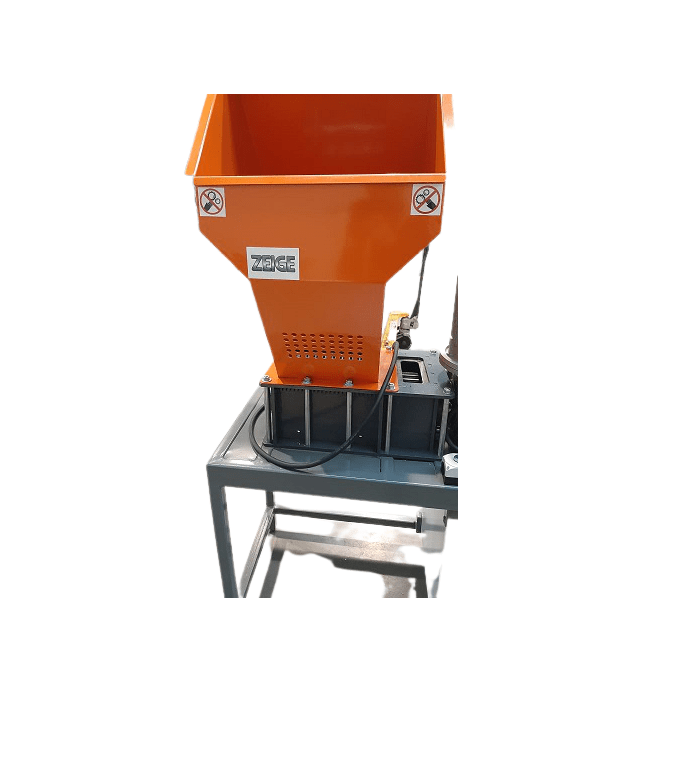

Shredder for plastics, cardboards and other waste – ZEIGE 300 shredder

This shredder is very durable and reliable. Everything has been calculated and constructed to withstand the heavy loads required to shred plastic.

Most industrial grinding systems require a grinding phase and a granulation phase. With adjustable grids, this machine can do both!

This shredder is also designed to be easy to clean.

Granulation is only possible with this grinder, but this step will still be slightly slower than with a dedicated industrial granulator. This machine is mainly intended for grinding.

The machine can grind any plastic of any shape that fits between the blades. We tested it with HDPE, PP and PS. The shredder has no restrictions on thickness. If the piece of plastic is too thick, the blades will not fray because the machine is designed so that the plastic cannot bind the machine (this depends on the power of the motor). PP, HDPE, PS from 0.7mm to 12mm have been tested successfully. The foils are too thin and slide between the blades. Rubbers, tires and thermosets have not been tested.

Fractions – size of the obtained material.

Various fractions can be obtained: large 0-30 mm, medium 0-10 mm, small 0-7 mm.

To obtain these sizes, an appropriate grid must be used. Install a 7mm sieve for small flakes or a 10mm sieve for medium size flakes. Larger sizes can be obtained without using a sieve. Depending on the size of the input material, it may be necessary to grind several times to obtain the desired size.

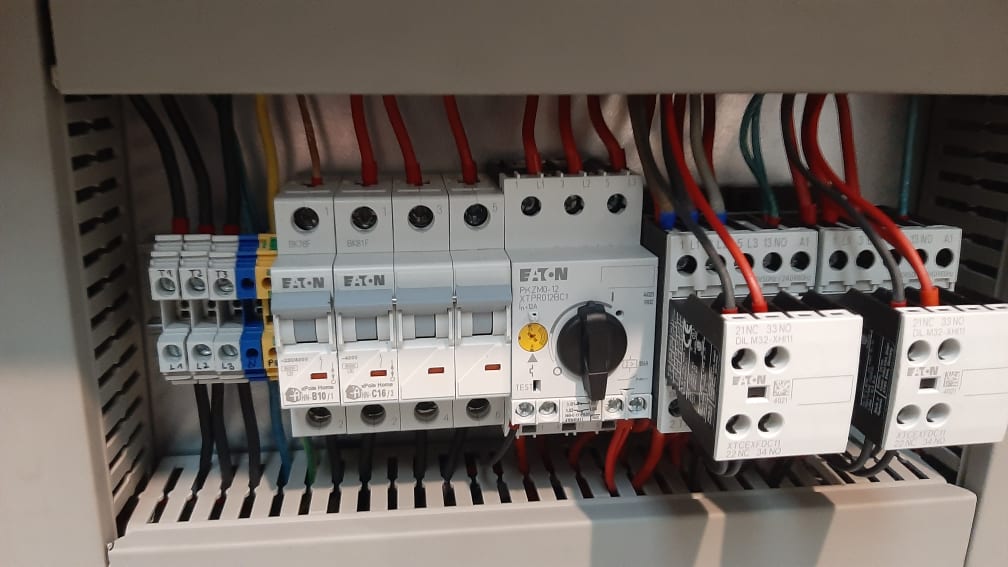

All the energy needed to shred plastic comes from the electric motor. More energy means greater efficiency and smaller flakes. The double shaft shredder operates at low speed and high torque, so the motor must meet these requirements.

Our machine uses a 5.5kW engine – thanks to this, it will be possible to fully use the capabilities of the shredder.

The machine is equipped with a clutch to prevent faster wear of other components.

The 45mm diameter roller ensures that the mechanism does not deform.

The machine is available in several variants, depending on the customer’s needs, we will select the appropriate size of knives and engine.

Technical data:

Mechanism dimensions: 300x250mm

Inlet dimensions, upper part: 515x480mm

Machine drive:1 x3.5 KW (electric motor)

Drive transmission: gear

Clutch:none

Number of drive shafts: 2 pcs

Number of knives: 26 pcs

Knives thickness: 6 mm

Machine dimensions: 1670x1410x600mm

Efficiency: 40 kg/h

Construction: light housing